The late Nineteen Eighties have been the heyday of the screen-printing craze. This printing methodology allowed customers to order giant quantities of self-designed graphic shirts.

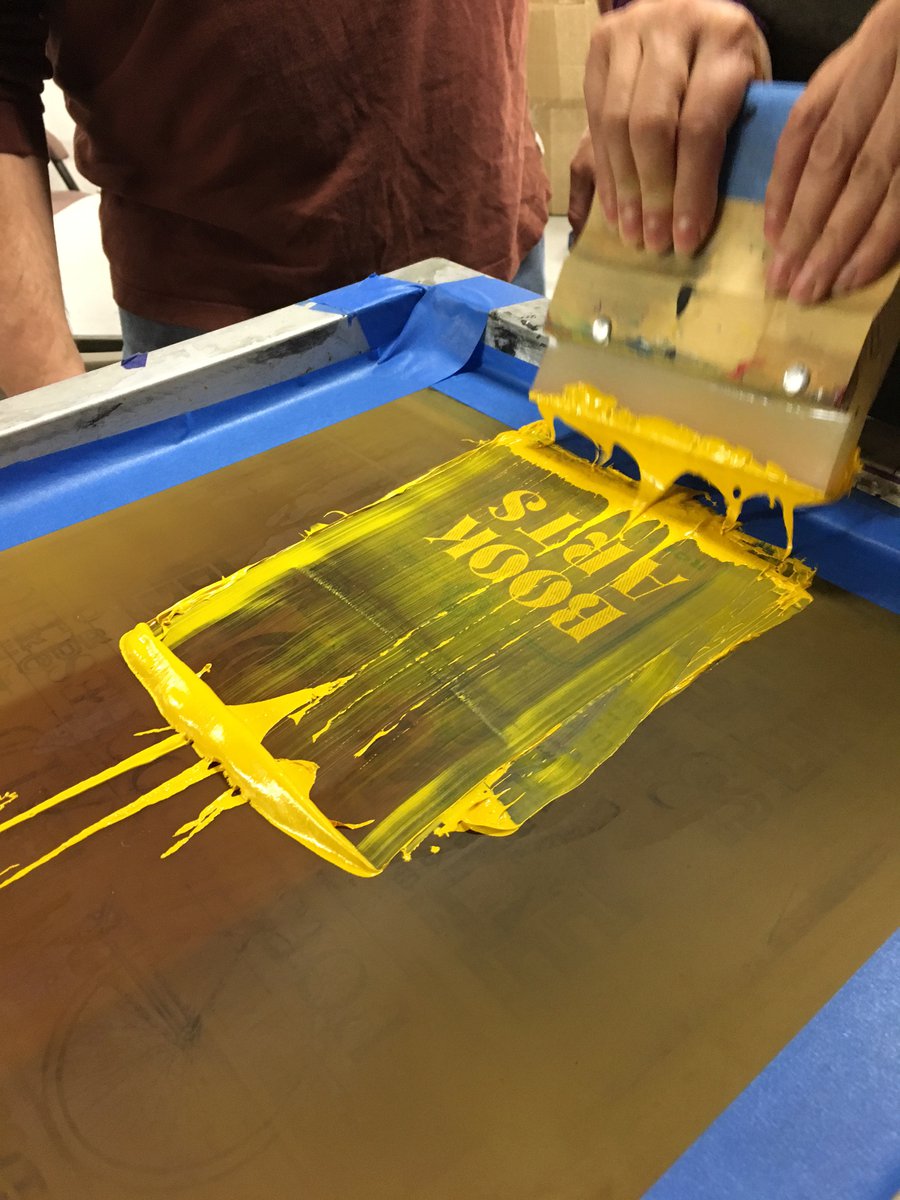

While there are automated screen print presses, the process itself is still typically carried out by hand, pressing the ink across the screens with squeegee. When the design is completed, you can feel the ink on the fabric.

T-shirt printing is amongst the most thriving businesses across the globe today. However, not everybody who begins this enterprise is assured success because many have shut down due to poor decision-making. One of the most crucial errors people make is choosing the Direct To Garment Printing Vs. Screen Printing technique. Several components must be kept in mind first earlier than you start t-shirt printing design. The means of utilizing a printer head to apply ink on to a bit of apparel of cloth. When it comes to high quality, there is really no difference between DTG and silk screening.

What is one of the best, highest quality printing technique for printing classic black and white pictures on t shirts. This is not a commercial printing method as you cannot print on a large scale with this methodology. Using stencils to print on the material is labour intensive especially when lots of t-shirts are involved, But for a DIY t-shirt version, this is the best methodology. Check out this submit on some tips to make a stencil and more particulars on 7 stencil painting strategies. Special cut-outs are applied to the t-shirt using an industrial warmth press.

You can fire up the printer, pre-treat shirts, and ship them off after printing & curing very quickly in a pinch. You can print full-color photographs and other difficult high-color-count art with DTG printing easily. Most shops apply pre-treat with a roller or pre-treat machine. Pre-treat chemical compounds value barely less than DTG ink however are still a considerable expense. Pre-treating adds one other minute of time to each garment you print.

We are pleased to reveal all three methods to our customers to assist them pick the best print method for them. It should be famous that simply because DTG printed shirts cost lower than silk screened ones, that doesn’t imply their high quality is any less. The DTG printers we use at One Hour Tees are state-of-the-art and have a really high resolution.

Unless you focus on printing complex art, lean towards DTG for issues like pictures . If you construct a business mannequin that may accommodate small orders, DTG printing can be highly worthwhile andeffective.

The shirt is then digitally printed according to the design in the printer queue. In addition to DTG printing, our company additionally offersscreen printing services in Philadelphia. If you’re uncertain which print technique is right for you, reach out to us at present. The first step to your t-shirt printing using DTG is pretreatment. It’s like adding a primer earlier than printing to help colours adhere better to the material.

The output is far greater than a conventional applied screen printing process. Operating a DTG machine is way less complicated than a display screen printing counterpart.

If you see that art work can simply be separated, lean towards display printing. The screen is placed on a display printing press and registered so it will correctly align on the printing surface (typically, a t-shirt). Ink is pressed via the openings within the stencil with a squeegee, immediately making use of ink onto the printing surface. With DTG it actually relies upon if the printer has aspecialized platen(or if there’s even one available) that fits the garment location you’re trying to get printed. This can be true for screen printing, however there are many extra platens out there. It’s simpler to tell you what fabrics youcan’t display screen print on.

Nowadays, screenprinting is finished both by machines and by hand. Once the shirt is pretreated and dried, we then place the shirt into the DTG printer, load up the digital artwork we’ve prepared from your design, and the printer goes to work.

Each and every worker shall be your advocate whereas navigating the numerous choices inherent with custom display printing, embroidery, indicators, and promotional merchandise. We provide clear, equitable pricing and are at all times open to debate the variables which drive value and how one of the best value may be obtained. Selecting clothes, growing paintings, and receiving a final product that exceeds your targets must be simple and seamless. Our digital attire printing inks had been designed to attain the best stage of quality obtainable. The inks are particularly designed for quite a few washes previous to fading or cracking.

This DTG printer is appropriate for printing a number of garments at a time. A single machine that may print three numbers of XXXXL outsized clothes, six numbers of ordinary clothes, or 12 numbers of smaller clothes. From small to large-scale printers, the DTG printer is appropriate for all customized decorators.

Both Digital and display screen will look nice, crisp and clear as long as the source art is nice. Screen print is massively versatile in ink variations and technical capabilities. Digital printing’s blues and violets simply don’t look good on an underneath base. It also doesn’t have the specialty inks display screen printing has like metallics, glow at midnight and UV delicate colours.

These strategies might achievementlearn.com/category/printing/ be a watch opener to many prospect customer and novice enterprise starters. The Revolution printer was supplied for sale until 1998 when Rhome left the corporate to start out development of the primary Brother DTG printer, which came to market in 2005.

Each color used within the design is printed separately with its own screen. This means your design should first be damaged down into completely different layers by color.